ASME A112.19.2:2008 pdf download.Ceramic plumbing fixtures.

6.1.5 Performance

The average absoption of the three fragments shall not exceed 0.5% for vitreous china and 15% for non-vitreous china.

6.2 Crazing test

6.2.1 lest specimen

The test specimen shall be a fragment of a fixture with a glazed surface of approximately 3200 mm2

(5.0 in2) and not more than 16mm (0.63 in) thick.

6.2.2 Procedure

The crazing test shall be conducted as follows:

(a) Immerse the specimen in a solution of equal portions by weight of anhydrous calcium chloride and water.

(b) Maintain the solution at a temperature of 110 ± 3 C (230 ± 5°F) for 90 mm.

(C) Remove the specimen and immediately immerse it in an ice water bath at 2.5 ± 0.5 C (37 ± 1°F) until chilled.

(d) Remove the specimen from the bath and immerse it for 12 h In a 1% solution of methylene blue dye at room temperature.

(e) Remove the specimen and examine it for craze lines, as indicated by penetration of the blue dye.

6.2.3 Perforniance

There shall be no crazing.

6.3 Surface examination

6.3.1 Procedure

Surface finishes shall be examined for defects by the unaided eye approximately 610 mm (2 ft) directly above the rim while the specimen is rocked to each side and backward to an angle of approximately 45°. The light source used to examine surface finishes shall be partially diffused daylight supplemented, ii necessary, with diffused artificial light, giving an illuminance on the surface of a minimum of 1100 lx (102 foot-candIes).

Note: Unaided eye includes vision assisted by co.’recffi’e lenses normafiy worn by the person inspecting the specimen.

6.3.2 Evaluation

6.3.2.1

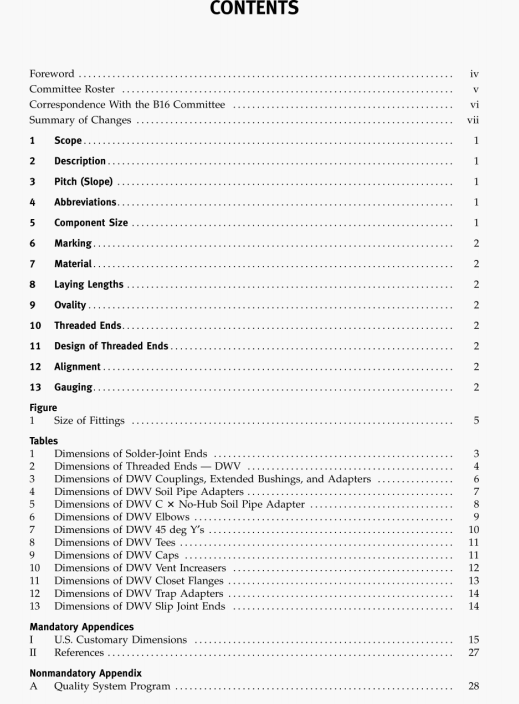

Water closet bowls, tanks, and urinals shall be evaluated in accordance with Clause 6.3.2.3 and Table 1.

Defects that exceed the maximums specified in Table 1 shall be cause for rejection of the fixture.

The average absoption of the three fragments shall not exceed 0.5% for vitreous china and 15% for non-vitreous china.

6.2 Crazing test

6.2.1 lest specimen

The test specimen shall be a fragment of a fixture with a glazed surface of approximately 3200 mm2

(5.0 in2) and not more than 16mm (0.63 in) thick.

6.2.2 Procedure

The crazing test shall be conducted as follows:

(a) Immerse the specimen in a solution of equal portions by weight of anhydrous calcium chloride and water.

(b) Maintain the solution at a temperature of 110 ± 3 C (230 ± 5°F) for 90 mm.

(C) Remove the specimen and immediately immerse it in an ice water bath at 2.5 ± 0.5 C (37 ± 1°F) until chilled.

(d) Remove the specimen from the bath and immerse it for 12 h In a 1% solution of methylene blue dye at room temperature.

(e) Remove the specimen and examine it for craze lines, as indicated by penetration of the blue dye.

6.2.3 Perforniance

There shall be no crazing.

6.3 Surface examination

6.3.1 Procedure

Surface finishes shall be examined for defects by the unaided eye approximately 610 mm (2 ft) directly above the rim while the specimen is rocked to each side and backward to an angle of approximately 45°. The light source used to examine surface finishes shall be partially diffused daylight supplemented, ii necessary, with diffused artificial light, giving an illuminance on the surface of a minimum of 1100 lx (102 foot-candIes).

Note: Unaided eye includes vision assisted by co.’recffi’e lenses normafiy worn by the person inspecting the specimen.

6.3.2 Evaluation

6.3.2.1

Water closet bowls, tanks, and urinals shall be evaluated in accordance with Clause 6.3.2.3 and Table 1.

Defects that exceed the maximums specified in Table 1 shall be cause for rejection of the fixture.