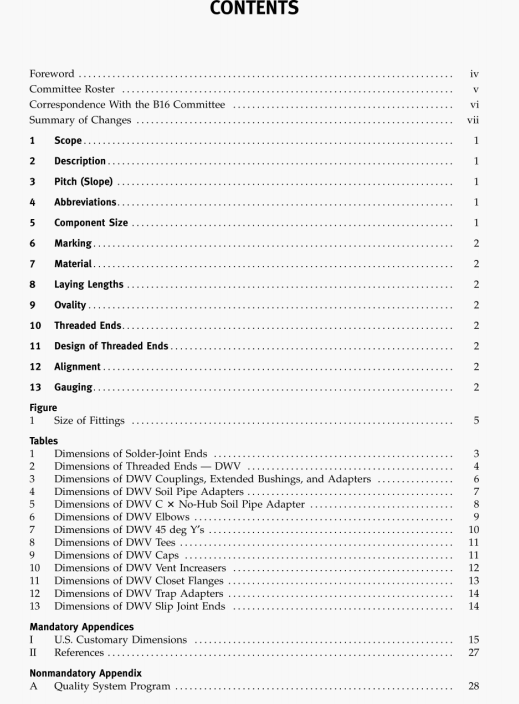

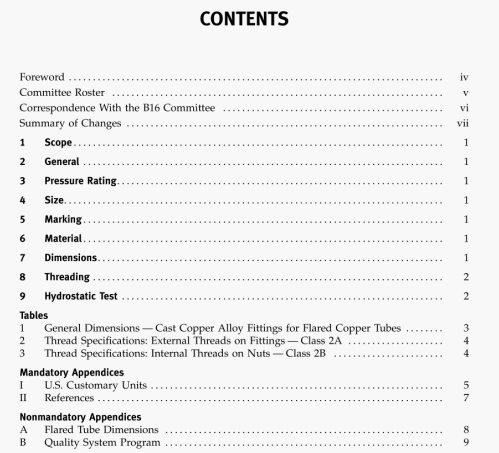

ASME B31G:2012 pdf download.Manual for Determining the Remaining Strength of Corroded Pipelines.

1.12 FLaw Interaction

The methods described herein are suitable for evaluating isolated areas of metal loss. Corrnsion may orcur such that multiple areas of metal loss are closely spaced longitudinally or transversely If spaced sufficiently closely, the metal loss areas may interact so as to result in failure at a lower pressure than would be expected bawd on an analysis of the separate flaws. The following guideline is suggested with reference to Fig. 1.12-I, based on Limited testing and analysis:

(a) Flaws are considered interacting if they are spaced longitudinally or circumfercntially from each other within a distance of 3 tim.es 11w wall thickness (31). Interacting flaws should be evaluated as a single flaw combined from all interacting flaws.

(b) Flaws are considered noninteracting if spaced outside of the above dimensions. Noninteracting flaws should be evaluated as separate flaws.

Care should be exercised when grouping or clustering anomalies indicated by inline inspection for purposes of evaluating interaction during the prioritization process. Consideration should be given to minimum thresholds of metal loss for reliable detection and sizing, minimum thresholds for reporting. and the expected mode of coating failure (e.g.. localed failure versus disbondment over large areas). Methods employed for clustering of inline inspection anomalies should be validated by field verification of actual flaw dimensions and spacing.

1.13 Flaw Orientation

Corrosion caused by disbandment of continuous wrapped coatings may exhibit a helical pattern. If the helical pattern lies at an angle less than 45 deg to the pipe axis, the overall length of the corroded area indicated as L, in Fig. 1.13-1 shall be considered in the evaluation. If the helical pattern lies at an angle of 45 deg or greater to the pipe axis it is sufficient to consider the most severe longitudinal section through the corroded area having a length L2 in Fig. l.l3-l.

The methods described herein are suitable for evaluating isolated areas of metal loss. Corrnsion may orcur such that multiple areas of metal loss are closely spaced longitudinally or transversely If spaced sufficiently closely, the metal loss areas may interact so as to result in failure at a lower pressure than would be expected bawd on an analysis of the separate flaws. The following guideline is suggested with reference to Fig. 1.12-I, based on Limited testing and analysis:

(a) Flaws are considered interacting if they are spaced longitudinally or circumfercntially from each other within a distance of 3 tim.es 11w wall thickness (31). Interacting flaws should be evaluated as a single flaw combined from all interacting flaws.

(b) Flaws are considered noninteracting if spaced outside of the above dimensions. Noninteracting flaws should be evaluated as separate flaws.

Care should be exercised when grouping or clustering anomalies indicated by inline inspection for purposes of evaluating interaction during the prioritization process. Consideration should be given to minimum thresholds of metal loss for reliable detection and sizing, minimum thresholds for reporting. and the expected mode of coating failure (e.g.. localed failure versus disbondment over large areas). Methods employed for clustering of inline inspection anomalies should be validated by field verification of actual flaw dimensions and spacing.

1.13 Flaw Orientation

Corrosion caused by disbandment of continuous wrapped coatings may exhibit a helical pattern. If the helical pattern lies at an angle less than 45 deg to the pipe axis, the overall length of the corroded area indicated as L, in Fig. 1.13-1 shall be considered in the evaluation. If the helical pattern lies at an angle of 45 deg or greater to the pipe axis it is sufficient to consider the most severe longitudinal section through the corroded area having a length L2 in Fig. l.l3-l.