ASME B16.18:2001 pdf download.CAST COPPER ALLOY SOLDER JOINT PRESSURE FITTINGS.

8 INSPECTION TOLERANCE

8.1 Linear Dimensions

An inspection tolerance as shown in Table 2 shall be allowed on center-to-shoulder, center-to-center, center-to-threaded end, and shoulder-to-threaded end dimensions on all fittings having female solder (solder cup) ends, and on center-to-solder end and solder-to- threaded end dimensions on all fittings having male soldcr (fitting) cnds.

Coupling inspection limits for shoulder-to-shoulder and shoulder-to-end dimensions shall be double those shown in Table 2, except that the minus tolerance applied to dimensions M. N, and W. and Tables 7 and B7 shall not result in a dimension less than 0.06 in. (1.5 mm) for sizes I/4 through I in.. inclusive, or a dimension less than 0.09 in. (2.3 mm) for the larger sizes.

The largest opening in the fitting governs the tolerance to he applied to all openings.

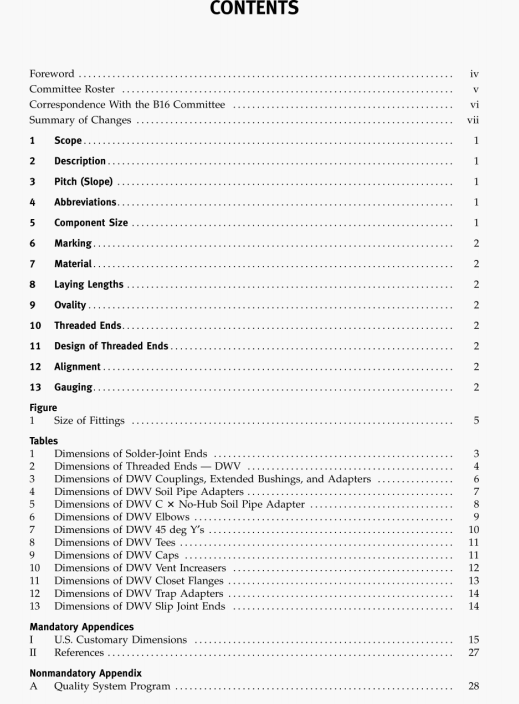

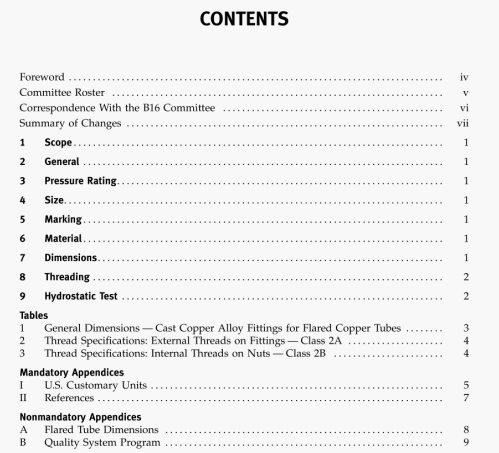

Tables 3 through 19 offer dimensions for pressure fittings covcrcd by this standard.

8.2 Ovality

Maximum ovality shall not exceed 1% of the maximum diameters shown in Table 3 or Table B3. The average of the maximum and minimum diameters must he within the dimensions shown in the table.

8.3 Gaging of Solder Joint Ends

8.3.1 Standard Gaging Method. The standard method of gaging the diamctcr tolerances for male and kmalc ends shall be by the use of plain plug and ring gages designed to hold the product within the limits established in Table 3 or H3.

8.3.2 Optional Gaging Method. For gaging the diameter tolerance of male and finale ends, the manufacturer may use direct reading instruments instead of ring and plug gages as specified in pam. 8.3.1. When gaging the diameters of male and female ends using direct reading instruments, refer to para. 8.2.

8.1 Linear Dimensions

An inspection tolerance as shown in Table 2 shall be allowed on center-to-shoulder, center-to-center, center-to-threaded end, and shoulder-to-threaded end dimensions on all fittings having female solder (solder cup) ends, and on center-to-solder end and solder-to- threaded end dimensions on all fittings having male soldcr (fitting) cnds.

Coupling inspection limits for shoulder-to-shoulder and shoulder-to-end dimensions shall be double those shown in Table 2, except that the minus tolerance applied to dimensions M. N, and W. and Tables 7 and B7 shall not result in a dimension less than 0.06 in. (1.5 mm) for sizes I/4 through I in.. inclusive, or a dimension less than 0.09 in. (2.3 mm) for the larger sizes.

The largest opening in the fitting governs the tolerance to he applied to all openings.

Tables 3 through 19 offer dimensions for pressure fittings covcrcd by this standard.

8.2 Ovality

Maximum ovality shall not exceed 1% of the maximum diameters shown in Table 3 or Table B3. The average of the maximum and minimum diameters must he within the dimensions shown in the table.

8.3 Gaging of Solder Joint Ends

8.3.1 Standard Gaging Method. The standard method of gaging the diamctcr tolerances for male and kmalc ends shall be by the use of plain plug and ring gages designed to hold the product within the limits established in Table 3 or H3.

8.3.2 Optional Gaging Method. For gaging the diameter tolerance of male and finale ends, the manufacturer may use direct reading instruments instead of ring and plug gages as specified in pam. 8.3.1. When gaging the diameters of male and female ends using direct reading instruments, refer to para. 8.2.