BS EN IEC 63093-9:2020 pdf download.Ferrite cores- Guidelines on dimensions and the limits of surface irregularities Part 9: Planar cores.

5.4Cracks

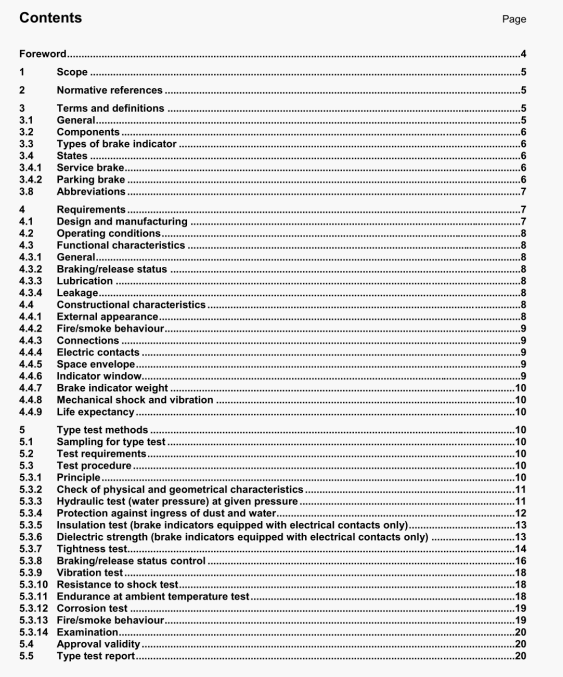

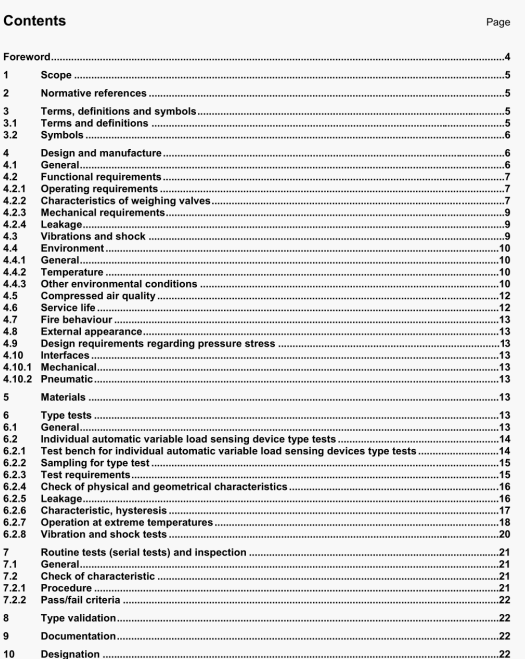

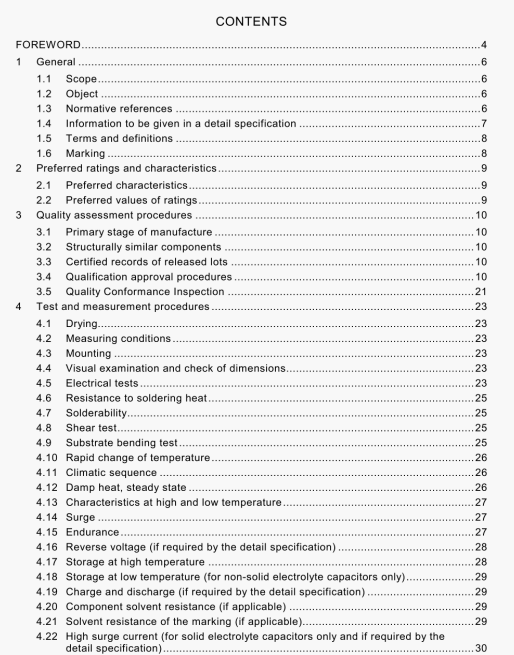

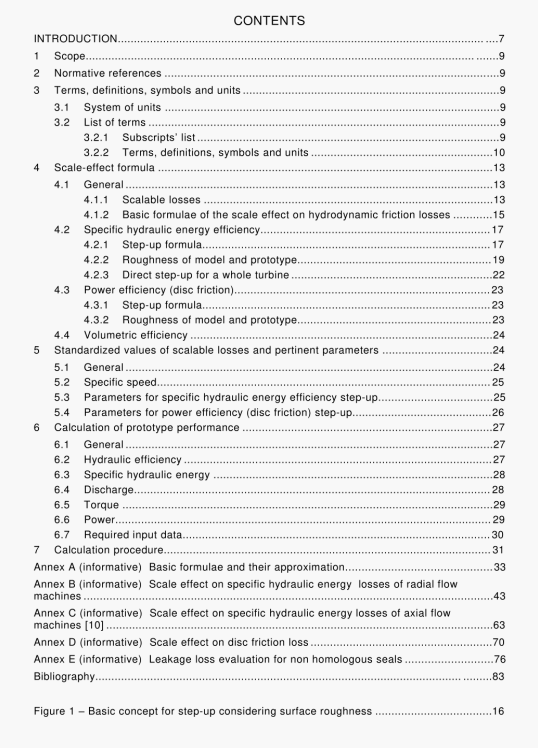

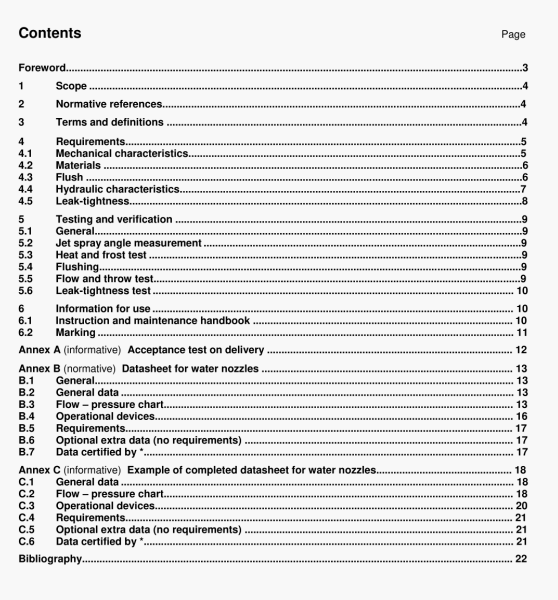

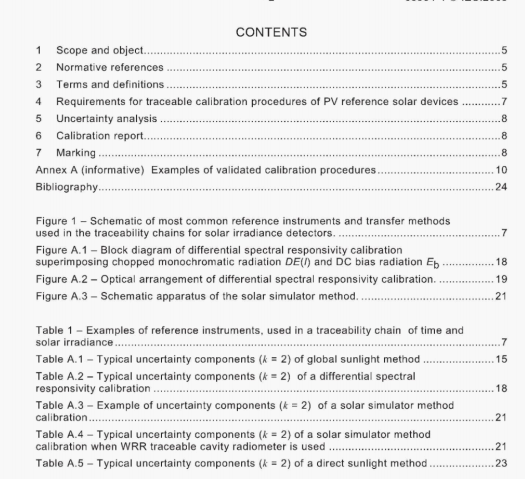

Different cracks are shown in Figure 10,Figure 11 and Figure 12. In principle three differenttypes of cracks can be distinguished.

a) Cracks which are parallel to the magnetic flux path(S1,S2,S5,S5',S5"). These cracks

are magnetically not critical.The maximum length of a single crack is 33 % (1/3) of thedimension of the relevant surface which is parallel to the crack. In the case of multiplecracks the maximum cumulative length doubles.

b) Cracks which are perpendicular to the magnetic flux path (S3,s3',S3",S4,S4').These

cracks are magnetically critical. They can reduce the 'relative cross-section of themagnetic flux or add an additional air gap into the magnetic circuit. The maximum totallength of cracks is 20 % (1/5) of the dimension of the relevant surface which is parallel tothe crack.

c) Cracks which go from one edge to another edge (S6).These cracks can cause chipping

during the operation in the circuit.The loose particles can cause malfunctions in the circuit.Therefore this type of crack is not acceptable in any case.

The reference dimensions are given in Figure 13,Figure 14 and Figure 15.

The limits for cracks are given in Table 8,Table 9 and Table 10.

5.5 Flash

There shall be no flash extending from the core into the wire slot.

5.6 Pull-outs

The pull-outs are applicable only for the inner surface where the PCB is seated (as shown in Figure 10,Figure 11 and Figure 12).

For planar EL-cores, low-profile E-cores and low-profile ER-cores, the cumulative area of pull-outs of the core shall be less than 20 % of the total respective surface area.